‘Why we are putting up factories in the countryside’

Sponsored by Devki Group of Companies

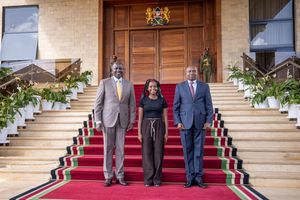

Dr Narendra Raval, Chairman of Devki Group of Companies, during the commissioning of Cemtech Sebit Clinker Plant in West Pokot County, on April 8, 2024. The chief guest was President Dr William Ruto.

What you need to know:

- Steel and cement industrialist Dr Narendra Raval, the executive chairman of Devki Group of Companies, reflects on the last three decades as the company officially launches its new Cemtech Limited clinkerisation plant in Sebit, West Pokot County.

By Millicent Mwololo

Q. Give an overview of Devki Group of Companies

Devki Group of Companies is over 30 years old. Our mission is to make sure that Kenya becomes a big exporter of cement, steel, and roofing sheets.

We have over 11,000 Kenyans working directly with the group. In Uganda, we have 600 employees, while in Rwanda, we have employed 250. Our vision is that by 2027/28 after expansion, we will provide direct employment to about 25,000 Kenyans. We plan to invest over $550 million in the next four years.

Having the factories in rural areas changes their economies. We have established our factories outside of Nairobi to change the perception that the way of developing our country is to establish factories in the capital city. We are taking job opportunities to the communities.

In Emali, Makueni County, we have employed over 2,000 Kenyans, and more than 37 percent are the local Maasai people. This has changed the neighbourhood socio-economically. It is now popular as ‘Simba’ town, in reference to Simba Cement. The money in circulation has increased; the quality of life too.

In the community, we sponsor the education of almost 8,000 children. We provide them with food through a feeding programme with the schools. In the public schools, we build extra classrooms and pay salaries to the extra teachers so that more children can be accommodated to access education. In Bamburi in Mombasa County, the group has employed over 800 people, and has sponsored several schools and school feeding programmes.

The new Cemtech plant is poised to change the perception of the community in West Pokot and that of Kenya, as the plant will produce clinker for export. In one year’s time, our Samburu steel plant has saved the country $600 million in foreign exchange because it has increased local production of steel. This stopped the importation of steel into the country – a very big game-changer for Kenya.

Q. How has the new factory enhanced the standards of living and economic growth in West Pokot?

The new factory has enhanced the quality of life for not only the people working there, but also the surrounding community. There is a small shopping centre next to our factory called Sebit. Previously in Sebit, there were only two or three kiosks, and hardly could you see anyone after 8pm.

We’ve had almost between 4,000 and 5,000 people working on the project, and all the raw materials come from Pokot. Two years down since we started the project, the money in circulation has improved.

Sebit is now a busy town with hundreds of people operating day and night. The economy is growing and this is the effect we wanted. The Pokot are a very nice community. I am very proud that I have invested there.

An elevated view of the new Cemtech clinkerisation factory in West Pokot. Cemtech Ltd is a subsidiary of the Devki Group.

Q. Do you always get the talent you need, locally?

In situations where circumstances did not allow some people to study, we train them to acquire the necessary skills. We have done it in Emali, Samburu, and now in West Pokot.

Q. What measures have you implemented to ensure environmental sustainability?

We are the first company in Kenya to put up a clinker plant in Emali, and in Pokot. The heat produced, almost 800°C, is not released into the environment. We have waste recovery strategies. In Emali, we produce 15MW of power from the waste. In Pokot, we produce between 7.5MW and 8MW from waste. This also reduces the company’s power bills.

_______________

For more information about Devki's growth strategy and Dr Raval’s views on investments, click here.