Premium

Chalk business capitalises on home-grown solutions

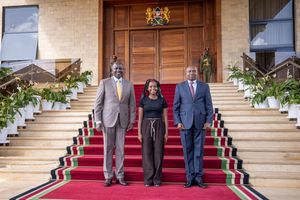

Leah Warii, the founder of Warii Gypsum Limited. The company produces affordable high-quality dustless blackboard chalks for schools across the country.

What you need to know:

- Warii Gypsum commenced operations in 2022 with modest chalk production to test the market.

- The inception of Warii Gypsum was inspired by the gap in the market for high-quality, affordable blackboard chalk tailored specifically for African schools

As the founder of Warii Gypsum Limited, Leah Warii channels her passion for education into a thriving business that produces affordable, high-quality blackboard chalk for schools across Kenya.

An alumnus of Jomo Kenyatta University of Agriculture and Technology, her Business and Information Technology degree provides her with the essential skills to operate a modern enterprise.

Motivated by a commitment to sustainable business practices and addressing relevant educational and employment needs, Warii recognised a significant opportunity in the gypsum sector.

“My motivation to invest in this sector stemmed from my commitment to establishing a sustainable business that addresses educational and employment needs. I recognised a valuable opportunity to supply quality, affordable blackboard chalk to schools across Africa, and I aimed to empower young people through job creation and training,” she explains.

The inception of Warii Gypsum was inspired by the gap in the market for high-quality, affordable blackboard chalk tailored specifically for African schools.

Warii acknowledges that many educational institutions struggled to access durable, dust-free chalk that was safe for students and cost-effective. The existing options were often imported, expensive or locally produced with inconsistent quality.

She identified this challenge and seized the opportunity that would plug this gap and build her business.

“By producing locally, we not only ensured quality control but also kept costs low, making the product accessible to educational institutions while fostering local community empowerment through employment and training opportunities,” she says.

Chalk production

Warii Gypsum commenced operations in 2022 with modest chalk production to test the market. The initial capital of Sh100,000 was entirely self-funded, drawing on personal savings to finance raw materials, essential equipment, and initial production expenses.

Dustless chalks manufactured by Warii Gypsum Limited a company founded by Leah Warii.

“We reinvested profits into the business to gradually scale up production and improve product quality, enabling sustainable growth while ensuring cost efficiency," she states.

The chalk manufacturing process involves several key steps, beginning with sourcing raw materials, primarily gypsum, along with water and additives to enhance quality.

The gypsum is then ground into a fine powder and mixed with water and additives to create a smooth paste. This paste is poured into moulds to form uniform chalk sticks, which are dried using air or kilns to ensure durability.

After drying, the chalk is smoothed and inspected for quality, focusing on dust levels and breakage resistance. Finally, the finished chalk is packaged for distribution to schools and retailers.

Warii says that throughout the process, stringent quality control measures are implemented to guarantee that the final product is consistently dust-free and smooth.

Her choice to utilise locally sourced gypsum has significantly transformed her business. By eliminating reliance on imported materials, she has not only reduced production costs, but is also doing her bit to grow the local economy.

“This decision has enhanced the quality of our chalk and also allowed us to offer competitive pricing while developing stronger relationships with local suppliers,” she explains.

Committed to maintaining the highest quality standards in dustless chalk production, the company employs a variety of strategies. This begins with sourcing premium-grade gypsum to achieve the desired texture and durability.

“We carefully formulate a mix of additives that enhances the chalk’s texture and minimises dust production during use,” she adds.

The manufacturing process incorporates advanced moulding and drying techniques, ensuring uniformity and durability while minimising crumbling. Rigorous quality control testing is conducted throughout production, guaranteeing that each batch meets strict standards.

Additionally, “continuous feedback from schools is essential for refining our product and upholding the dustless qualities that our customers expect,” she says.

Warii says that launching her business came with significant challenges that she tackled with determination and calculated foresight. One major obstacle was limited capital; she utilised personal savings to produce an initial small batch of chalk and reinvested profits to grow the business without incurring debt.

Navigating a male-dominated industry posed another challenge, as she encountered scepticism and bias. Cash flow management also proved difficult due to upfront production costs and delayed payments.

“To address this, I fostered strong relationships with clients and suppliers, negotiating better payment terms to improve cash flow. Additionally, tactical reinvestment boosted productivity and reduced operational costs. Initially, production efficiency was hindered by reliance on manual processes and outdated equipment,” she says, adding that as the business expanded, reinvesting profits allowed for necessary upgrades, significantly enhancing production capabilities.

To address the challenge of sourcing skilled labour, the company has developed a training program for local youth, equipping them with essential production skills.

Participants are trained on technical manufacturing processes, quality control standards, and safety practices to ensure high product quality. The program also incorporates entrepreneurial skills, teamwork, and communication, fostering collaboration and enhancing problem-solving abilities.

Since its inception, demand for learning materials, particularly chalk, has evolved significantly. Warii says there is a rising need for affordable supplies in low-income communities, and the locally-produced chalk meets this demand.

She explains that educators now prioritise high-quality, safe materials, which aligns with the company's commitment to producing “dustless, non-toxic chalk.” Additionally, she points out the growing preference for sustainable, locally sourced products.

To adapt, the company is diversifying its offerings to include creative educational tools and responding to the increased demand for resources that support hybrid learning environments.

To expand its market presence, the company is enhancing online marketing through social media and a dedicated website, enabling direct customer engagement and orders.

“Establishing partnerships with educational institutions will help secure long-term supply agreements, while participation in trade shows will showcase products and foster networking opportunities,” she says.

Additionally, community engagement through workshops will build trust and educate potential customers, while targeted advertising campaigns on social media aim to effectively reach specific demographics.

Serve wholesalers and schools

Noting that feedback from schools has been positive, Warii acknowledges that while educators appreciate supporting local businesses, suggestions for expanding the product range have also been noted.

The company’s pricing strategies aim to serve wholesalers and schools, ensuring competitiveness in each market segment. For wholesalers, the approach includes bulk discounts, competitive pricing backed by regular market research, flexible payment terms, and volume-based incentives to encourage larger orders.

For direct sales to schools, the company emphasises cost-effective pricing, with a particular focus on supporting lower-income institutions. They offer promotional deals at the beginning of the academic year and provide package options to enhance value.

“Currently, we employ 12 people, producing about 20,000 pieces of chalk daily, totalling approximately 600,000 pieces per month with plans to increase our production capacity early next year to meet the growing demand for our products,” she says.

To enhance production capacity and reach more schools in Kenya, the business has invested in advanced machinery to boost efficiency, expand its workforce, and create additional job opportunities within local communities.

The company plans to expand into remote areas and explore opportunities in the broader African market, particularly in East African nations such as Uganda, Tanzania, and Rwanda.

By targeting international schools and collaborating with NGOs, they aim to enhance their outreach and positively impact educational resources across the continent.

“I encourage aspiring entrepreneurs to view local markets as vibrant ecosystems. By being attuned to community needs and committed to quality, they can seize opportunities that benefit both their businesses and their communities,” she concludes.