Premium

Should brake fluid and coolant be renewed? If so, how often?

The most important quality of brake fluid is its boiling point

Hello Gavin, I look forward to your motoring articles, which are a must-read for me every Wednesday morning. Keep up the good work. To my question. Is Brake Fluid supposed to be replaced or is it a lifetime fluid? If there’s a recommended interval to replace, please advise and explain how to go about this. I would also appreciate advise regarding coolant.

Best regards, RT.

Short answer: Brake fluid can last in good condition for quite a long time (through many service intervals) but certainly not the lifetime of a vehicle. Most manufacturers recommend a lifespan of between two and three years. More than twice that long is not uncommon among users, with occasional top-ups giving some refreshment.

A mechanic adds brake fluid.

If you use part of a pot of fluid to top up, then whatever is left in the pot should be deemed expired after 12 months. In the same vein, if ever the brakes need “bleeding” (for instance to get rid of an air lock), the fluid bled off should be caught in a pot to avoid spillage pollution, but it should not be put back in the car’s brake fluid reservoir (except in a roadside emergency when no fresh new fluid is immediately available). The old stuff might still work and help you get home but it will be sub-standard.

Longer answer: The most important quality of brake fluid is its boiling point (about five times higher than the boiling point of water!). The higher the better, so even in severe use it does not vaporise or become aerated and lose some of its force in the hydraulic pressure system that operates the brakes. After all, braking hard from, say, 100 kilometers per hour to a near standstill even once (which Kenyan motorists do frequently thanks to unmarked speed bumps) the friction pads on the discs generate enough heat to boil a litre of water. Brake discs can glow red hot, and the fluid has an interface with that.

Brake fluid should also contain nothing that will allow corrosion. Rust on the hydraulic pistons can make them jam and/or progressively erode the metal until they leak and lose pressure.

Brake fluid “ages” through a decline in these two respects, mainly because it is hydroscopic – it absorbs water from the atmosphere. Even though the system is theoretically sealed, inevitably some water (even humidity in the atmosphere) does get in when the reservoir cap is opened or round the pistons at the wheel hub which move every time you touch the brake pedal.

Even tiny quantities of water can accumulate, not only allowing corrosion but actually promoting it, and the water element has a very low boiling point in brake-temperature terms, so it aerates the hydraulic fluid and compromises its physical integrity. The brakes get “spongey” and the boiling point of the fluid itself is halved when it is fully saturated with water.

So here is the regimen:

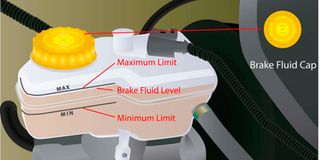

The brake fluid level should be checked whenever the bonnet is opened. It should be kept topped up to above the MIN line (and preferably up to the MAX line) at all times. Even if all is well, the level will fall slightly as the brake pads/linings wear thinner and need topping up until the brake pads/shoes are replaced.

Brake fluid is a completely clear liquid. No colour. No cloudiness. Water content makes it turn cloudy (a sign that water has mixed in) and become progressively brown (that’s a result of rust, and after extreme neglect it can turn almost black). At the first signs of it becoming anything but colourless and clear, it should be changed, completely drained out (flushed if necessary), the brake pistons should also be derusted and the system refilled, bled of all air, and firmly sealed.

As with the ‘best by’ dates on foodstuffs, the two-year or three-year limit is a guide, not “fine today/useless tomorrow” cliff edge.

Hot stuff and takeaways

The coolant for your engine is essentially water, preferably with an additive (some form of glycol, like anti-freeze) that will prevent corrosion and help lubricate the water pump.

The water pump is a sealed unit at the front of the engine, driven by the fan belt. It forces the coolant to circulate in its constant cycle from the bottom on the radiator into the “water jacket” channels of the engine block (where it draws heat from the engine) and then back through pipes to the top of the radiator, from where it flows through the finned radiator tubes (cooled by air entering the engine compartment and boosted by the fan), before returning to the bottom tank and beginning the cycle again.

Brake fluid can last in good condition for quite a long time but certainly not the lifetime of a vehicle

For the system to work properly, there must be enough coolant (filled up to the housing of the radiator cap), it must flow vigorously and rapidly through the whole cycle and must be well sealed and under pressure to prevent air bubbles, recapture steam and raise the boiling point, and it must be adequately cooled by lots of fresh air entering the engine compartment, boosted by the fan when necessary. If any of those ingredients is not present and correct, then some degree of overheating, whether slight or damagingly severe, is inevitable.

One of the most common causes of overheating, especially in older cars, is rust and other dirt in the system. This reduces the rate of cooling in the radiator tubes (it compromises the ability of the radiator fins to conduct heat away) and on the inside reduces the flow of coolant in the water jacket channels around the engine, allowing the coolant to spend too long in the walls of the engine block and become super-heated (and hence bubbly and steamy).

This problem is best prevented by regularly flushing the system with clean water and then refilling it with fresh water and a good quality coolant additive. It is cured by flushing with special fluids to remove the dirt/rust from the radiator tubes and water jacket channels. In severe cases, these might need to be physically scrubbed, inside and out and then flushed again. Dirt on the outside of the radiator fins (grass seeds or mud) also needs to be promptly removed…but carefully, as they are delicate material to optimise the conduction of heat.

Engine coolant.

As with brake fluid, discolouration of coolant is the sign that it is time to start afresh.

What else goes wrong?

If the fan belt breaks, or the water pump itself fails, circulation of coolant will stop and the engine will overheat almost immediately.

If any part of the system leaks (the tubes or the tanks of the radiator or the tubes connecting it to the engine), then coolant will be lost and the remaining volume will not be enough to absorb the engine heat and take it away for fan cooling. The engine will overheat to a progressively serious degree.

If the radiator cap spring is too weak, it will allow coolant to escape too easily and be lost to the outside world. It will also reduce the pressure of the sealed system, so the coolant will be weakened by air bubbles and steam.

The system also has a gadget called a thermostat (usually in a housing at the front of the cylinder head) whose job is to keep the engine temperature constant. When the engine is cold at first starting, the thermostat closes and shuts off coolant circulation so the engine warms up as quickly as possible.

When the engine reaches its designed operating temperature, the thermostat partially opens a valve and the cooling circulation begins. If the engine is working hard and generating more heat, the valve opens wider, if the engine generates less heat (gentle driving or very cold weather), the valve opening is reduced. By changing the size of the circulation valve, making it bigger or smaller according the circumstances, your engine temperature needle stays still…in the right place.

When thermostats go wrong the valve usually closes completely or will not open wide enough and overheating can be rapid and severe. A failed thermostat can be removed completely (on some systems a bypass valve must then be blocked) to allow a journey to continue, but coolant will then circulate as though the valve was wide open all the time. The engine will work well enough, but mostly at well-below its designed operating temperature – not good for combustion efficiency or the engine’s durability in the long term. A new thermostat should be fitted without undue delay.

What if oil flushing and fuel detergents don’t work?

Is there any way to clean piston rings without opening the engine? Please advise.

Regards, Zahir

Piston rings are the interface seal between oily parts of the engine the smoky/sooty combustion chamber in the cylinder head.

Bearing in mind that piston rings are the interface seal between oily parts of the engine the smoky/sooty combustion chamber in the cylinder head…

Two things have a “cleaning” effect without opening the engine: detergent additives in the fuel and oil, and flushing oil.

However, when piston rings fail to provide a good seal, the problem is not usually dirt, more often it is excessive wear or a broken ring, to which the only solution is to fit new rings. This does require the engine to be at least partially dismantled because that job is labour intensive (the parts are small and relatively inexpensive) it makes sense while the rings are being replaced to also check and renew any other severely worn inner parts – most commonly the bearings which connect the piston conrods to the crankshaft and the timing belt/chain – and to do a general clean and check of the whole unit. Dirt is often the culprit on things like valves, cooling channels and in the oily guts of the engine.

That would constitute what is known as a “minor” engine overhaul. A “major” overhaul is when other and often bigger parts are also replaced – things like the pistons themselves, the cylinder linings, the main crankshaft bearings, the oil pump, camshafts, tappets and so on.

When it comes to dismantling, conventional engines usually have four distinct sections. At the top is the lightweight valve cover (made of steel plate) which is just a lid to keep dirt out and oil-splash in. On engines with overhead camshafts, removing the valve cover gives access to the camshaft(s), valve stems and springs, and rocker arms/tappets.

The cover is bolted on top of the cylinder head (often made of aluminium) which contains the “roof” of the combustion chambers, the valve seats, the spark plugs and the inlet manifold from the carburetor and the exhaust manifold.

That head is bolted to the main engine block (usually made of cast iron), which contains the cylinders, the pistons and their conrods, the crankshaft, and the gearing that runs the various pulleys (which also have an equivalent of the valve cover at the front of the engine). This is the section that is connected to the clutch bell-housing and the gearbox, and where the engine mountings attach the whole engine to the chassis/frame of the vehicle. The walls of the block contain the main water channels of the cooling system.

At the bottom is the sump pan, which is the oil reservoir inhabited by an oil pump.

The interface of each section must have a highly specialised gasket to ensure a perfect seal. That’s the general pattern for most engines, whether transverse or in-line, and although shapes and orientation vary for V-shaped or horizontally opposed cylinder lay-outs, the same principles apply. Horizontally opposed engines are effectively like a V pressed flat.

For repair or replacement, the engine must be “opened” to whatever extent is necessary to reach the part that needs attention. The valve cover, cylinder head and sump can be removed individually or collectively while the engine is still in the car. Access to the engine block requires the engine (which can weigh several hundred kilos) to be removed from the engine compartment…unless you know a mechanic who is a contortionist, can see in the dark, who is also very good at origami, and has spanners with corners in them.

Do you have a motoring question, email: [email protected]