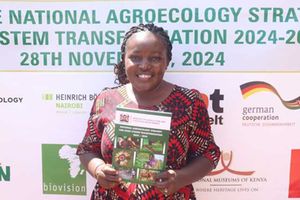

Jehu Oduor displays parts of the banana stem that are used to make juice at Kirdi Kibos, Kisumu Centre.

Many farmers grow bananas with the sole intention of harvesting the fruits for consumption or sale. Once the fruits mature, the trunk or pseudo-stem is cut to pieces and left in the farm to rot or given to livestock.

Jehu Oduor, a resident of Kisumu County, has turned what is waste to many farmers into a rare product. He now makes juice from banana trunks.

Oduor started the enterprise with four others.

The agribusiness idea was conceived during the Covid-19 pandemic, when Kenyans were looking for remedies to unclog congested chests.

He did some research on alternative remedies and came across banana trunk juice.

“I experimented at home using a blender to crush the inner soft tissue of the trunk. It was tedious but I got the juice eventually,” Oduor says.

He adds that the juice had no taste but discovered it had health benefits. The banana trunk has calcium, potassium, fibre and other minerals.

Oduor says the juice aids in digestion, improves the sugar level of the body, blood circulation and fights kidney illnesses.

The entrepreneur has been engaged in more research on enriching the juice with more nutrients.

He approached the Kenya Industrial Research and Development Institute (Kirdi) in 2023, seeking ways to produce quality juice.

At the Kibos Kirdi centre, Oduor learnt how to develop a more stable product for the market and pricing.

With his partners, Oduor established TBR Capital SME company with Sh250,000 capital drawn from their savings.

“The experts at Kirdi helped us improve the juice in terms of colour, taste and shelf-life. We experimented and blended the juice with ginger, lemon, roselle, beetroot, oranges and other flavours,” he says.

They also got machines to process the juice.

Oduor gets trunks from farmers in Kisumu, Siaya, Vihiga, Kericho and as far as Kisii counties.

“We insist on having freshly cut stems to avoid contamination. The gathered trunks are kept at Kirdi stores as they await processing,” he says.

Processing is usually on Monday, Wednesday and Friday. Making the juice begins with cutting the stem to get to the creamy and soft core.

With his six employees at Kibos Kirdi centre, Oduor washes the soft tissues and cuts them into small pieces before they are crushed.

He processes 150 kilogrammes of banana stem pulp on a working day.

An extractor is used to get the juice from the banana trunk. Oduor says the flavours are incorporated soon after.

Oduor settled on two colours for his product – yellow and red.

“We don’t add sugar or chemicals to our juice. Ginger and lemon are natural preservatives. Our juice has a shelf-life of nine months,” Oduor says.

The blended juice is pasteurised and chilled before being packaged in 500ml and one-litre bottles. The firm processes 600 to 1,000 litres of juice in a day.

Oduor says a 500ml bottle of juice goes for Sh400 while the 1,000ml bottle is Sh700.

He supplies the juice to Kajulu, Kibuye, Kombewa, Sondu, Maseno and other markets. Oduor says he also has clients in Trans Nzoia, Nairobi, Siaya, Kisii and Kericho counties.

The remains of crushed banana stem can be turned into briquettes and manure.

Last year TBR Capital SME was among the companies enrolled in the Innovative Solutions for the Food Loss and Waste Incubation Programme by the Food and Agriculture Organisation (FAO).

The seven-month programme, held in Kisumu equipped MSMEs with skills in post-harvest handling, cold chain management, value-addition and food preservation techniques.

“We got important lessons on digital marketing to reach more clients. Most businesses in Kenya struggle to find customers,” Oduor says.

“Banana trunks are littered everywhere, becoming an environmental and health hazard. Some even end up in rivers.”

FAO Deputy Country Representative, Hamisi Williams, says food loss and wastage remains a big challenge to the country’s food security and nutrition efforts.

Thirty percent of the food produced in Kenya goes to waste.

“This may look like a tiny fraction but it leads to shortages, forcing the government to import and food explore other alternatives to bridge the gap,” Hamisi says.

Participants were also trained on modern storage solutions, improved packaging and sustainable food recovery methods that help reduce spoilage and enhance shelf-life.

Oduor’s unique enterprise is not without challenges.

He says TBR Capital SME needs to have proper machines to continue producing quality juice.

“For now, we are still using the machines at the Kirdi centre but will not remain here forever,” Oduor says.

“We need to get our machines. Some of these gadgets are very expensive.”

The company also has to incur additional costs in getting the banana trunks from more distant places.